Workshop type CMM:The following is a brief introduction to the application range of CMM

27 May,2022

Workshop type CMM:The following is a brief introduction to the application range of CMM

Workshop CMM:application range of CMM

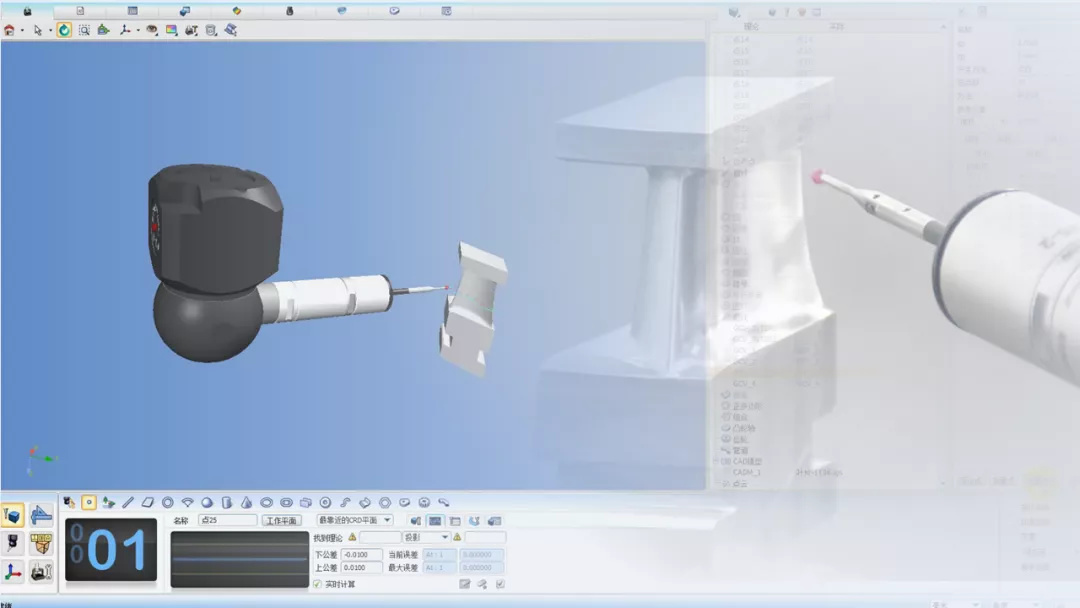

The coordinate measuring instrument is a new and effective tool for modern measurement and obtaining dimensional data.The use of the coordinate measuring instrument can replace various surface measuring tools and expensive combination gauges.The coordinate measuring instrument can reduce the time required for measuring complex objects from hours to minutes,so as to quickly and accurately evaluate dimensional data and provide useful data information for technical operators,This is very different from the traditional manual measuring equipment.By placing the measured object in the three coordinate measuring space,the coordinate positions of the measuring points on the measured object can be obtained.According to the spatial coordinate values of these points,the geometric size,shape and position of the measured object can be calculated.

The CMM is widely used in all walks of life,mainly for measuring boxes,racks,gears,cams,worm gears,blades,curves,curved surfaces,etc.,in the machinery,automobile,aviation,military,furniture,tool prototypes,machines and other small and medium-sized accessories,molds and other industries.In addition,it can also be used in electronics,hardware,plastics and other industries.The CMM can accurately measure the size,shape and tolerance of workpieces,Thus,the tasks of part inspection,shape measurement and process control can be completed.

Workshop type CMM:How to select a CMM software system?

When you determine that 3D is what you need,the 3D manufacturer will recommend appropriate software to meet the machine and applications.You should follow these suggestions.However,before making a decision,you should follow some common rules.

1.Easy to use

Simple measurement tasks need to be completed in a simple,obvious and intuitive way.At the same time,in software design,it is necessary to design according to human thinking logic to facilitate the control of the program.At the same time,it is also necessary to have online help to timely remind and help the measurement operators.In this way,the entire software only needs simple training,and the operators can carry out basic operation and maintenance.

2.Alignment of irregular shaped workpieces

When it comes to the alignment of datum plane and datum point of complex workpieces,the software needs a variety of alignment methods to adapt to the alignment of irregular geometric workpieces.

3.Scanning of unknown geometric quantities

This function allows measuring elements or complex surfaces to scan data points without knowing their nominal definitions.On an automatic measuring machine,the operator usually"self-study"the profile of the measuring cabinet by defining the starting point and end point of detection and the scanning density.

4.Programming language

Good measurement software often uses powerful and easy to understand programming language.The interface of dimension measurement information is realized through standard programming code,allowing the exchange between different measurement software based on DMIS.

5.Form and position tolerance

All types of geometric tolerance standards need to be implemented in measurement software,including lines and surface profiles.

Thank you for watching.See you next time.

Key words:

| Related news

27 May,2022

27 May,2022

27 May,2022