Application of CMM in Gear Quality Inspection

21 Apr,2015

Although some special measuring instruments used in traditional gear measurement(such as double side engagement tester,pitch measuring instrument,etc.)can measure the gear error more accurately,they are generally only used for the measurement of specific error items,with poor universality,and the measurement results are easily affected by human factors.As a universal measuring instrument,CMM has been used more and more widely in measurement and product quality control due to its advantages of high precision,strong function and convenient operation.The CMM can be equipped with a special gear measurement software module to measure gears with high accuracy.The measuring machine records the coordinates of the measured point through a high-precision probe,and obtains the error value by comparing it with the theoretical value.

Visual DMIS gear measurement module is mainly used to measure involute cylindrical gears,including internal teeth(straight teeth/helical teeth),external teeth(straight teeth/helical teeth)and their modified gears.A turntable is not required when measuring gears with Visual DMIS.

Output gear parameters can automatically determine the grade of measurement results according to different standards(such as ISO,DIN,JIS,AGMA,GB,BS).

It can measure and evaluate involute cylindrical spur(internal and external)gear and helical(internal and external)gear.It can also be used to measure and evaluate spur and helical gears with modification.

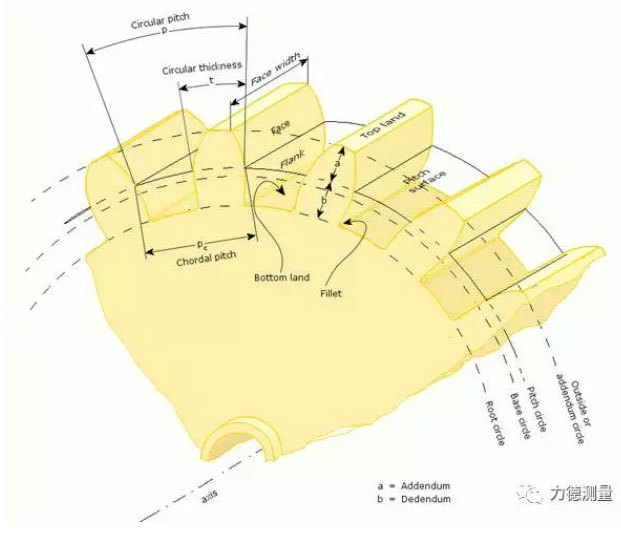

1.Be able to evaluate the gear tooth profile error(comprehensive error,tooth profile error,pressure angle error);Tooth alignment error(comprehensive error,tooth profile error,helix angle error);Pitch deviation;Adjacent pitch error;Error parameters such as cumulative error of pitch and radial runout of gear.

2.It can also measure and evaluate the gear tooth thickness,common normal length,span bar distance and other parameters.

3.According to different standards(such as ISO,DIN,JIS,AGMA,GB,BS,etc.),the results of the measured gear can be automatically judged.

4.The measurement and evaluation of gears are simple and intuitive.It can automatically generate the three-dimensional mathematical model of the gear to be measured according to the module,number of teeth,pressure angle and other parameters of the gear.According to the requirements of measurement,the measurement path can be displayed intuitively,and the whole gear measurement process can be simulated.

5.The software can automatically define the number and angle of measuring pins according to the condition of the gear to be measured,and can automatically calibrate each measuring pin defined.At the same time,it is also possible to manually select the measuring needle to be used in the measurement.The diversified selection provides the operator with more operation modes.

6.Intuitive and concise measurement operation interface.The operator only needs to fill in the relevant gear parameters such as module,number of teeth and pressure angle according to the prompts on the software interface,and drag the positioning elements into the corresponding positions to locate the position of the measured gear.It can automatically measure gears.The operator can also select and measure the gear parameters such as tooth shape,tooth direction and pitch according to his own needs.

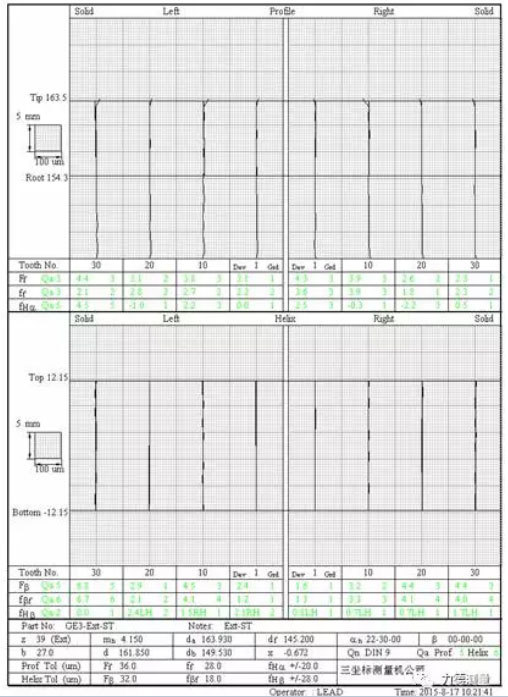

7.The evaluation of gear results and the output of measurement report are simple and convenient.Just drag the measured gear into the report display area,and the gear parameter errors such as tooth profile and tooth orientation will be displayed.And the measured data of each gear can be intuitively expressed by color whether it is qualified or out of tolerance.It can also give a grade evaluation for each measurement data.The test results can be saved or printed out.As shown in the figure below:

Key words:

| Related news

21 Apr,2015

21 Apr,2015

21 Apr,2015