Application of CMM in Extrusion Die Repair

21 Apr,2015

CMM can measure the coordinates of any point in X,Y,Z coordinate space,and the measurement accuracy can reach lμm.Its application software is also powerful,and it can also facilitate secondary development.It is used in different occasions.Many industries in China use CMMs as final inspection instruments.

As we all know,the key part of the extrusion die is the working zone of the die hole.The length,angle,shape and surface roughness of the working belt are the key factors affecting the profile forming and surface quality.At present,domestic extrusion plants rely on manual polishing to detect and correct the length and surface of the working belt with the help of angle gauge,knife edge ruler and micrometer.Its accuracy is often difficult to ensure.In addition,the skill level gap of operators also directly affects the effect after mold repair.After the introduction of CMM,the level of mold repair operators can be improved.

The measuring principle is as follows

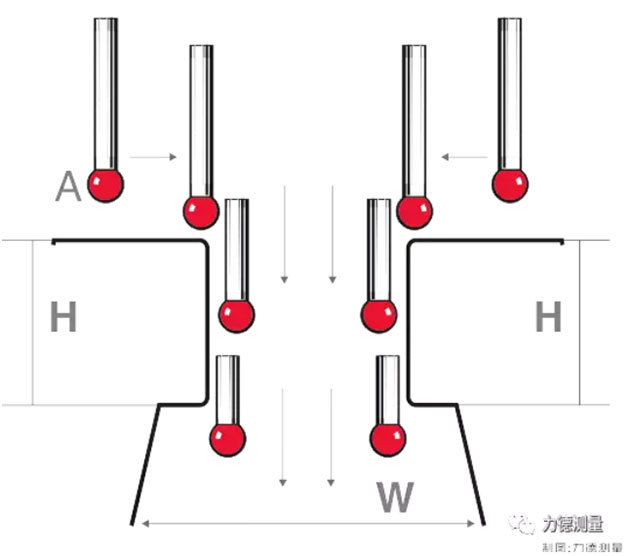

The measurement principle is shown in the figure below.First,establish a measurement reference plane on the mold surface,then place the probe at the edge of the working belt,start the corresponding detection program,probe A scans the points along the surface of the working belt,records the coordinate data of each point,returns the probe after the measurement,and the measurement process is completed.

Application Case of CMM Used to Analyze Die Problems of Profile Defects

After the extrusion die has been used for a period of time,or after multiple polishing operations,the working belt will be deformed to varying degrees.If the die in use can be regularly inspected with a CMM,problems can be found in advance and corrected to eliminate the occurrence of bad profile problems.

conclusion

CMM has played a considerable role in the actual use of the mold repair room,helping the mold repair personnel to improve their skills,and helping the mold repair personnel to analyze mold problems in production,providing reliable analysis data for the mold repair personnel,and the mold repair personnel are also used to regularly calibrate the angle gauges used in daily use.In addition,CMM can also be used to check and accept the quality of the new mold,such as the mold manufacturing workshop and the mold designer's feedback tendency and regularity data to improve the relevant processes.

Key words:

| Related news

21 Apr,2015

21 Apr,2015

21 Apr,2015