China's Heavy Weapon,Serving China through Space|Application of CMM in Aviation Industry

13 Jan,2022

Aeronautics and astronautics are the crystallization of wisdom and modern industry.On the other hand,the components of aerospace are very large.If you still use a tape measure to measure the dimensions of components,it is completely incompatible with this high-tech industry.Because aerospace components are huge,common measuring tools such as vernier calipers and dial indicators cannot be used due to range limitations.In addition,application scenarios in the aerospace industry usually require that all components closely cooperate to cope with high-speed,low temperature and high vibration environments,so the size measurement of aerospace components requires a large CMM with large measurement range,high accuracy and stability.

Application of precision measurement in aviation industry

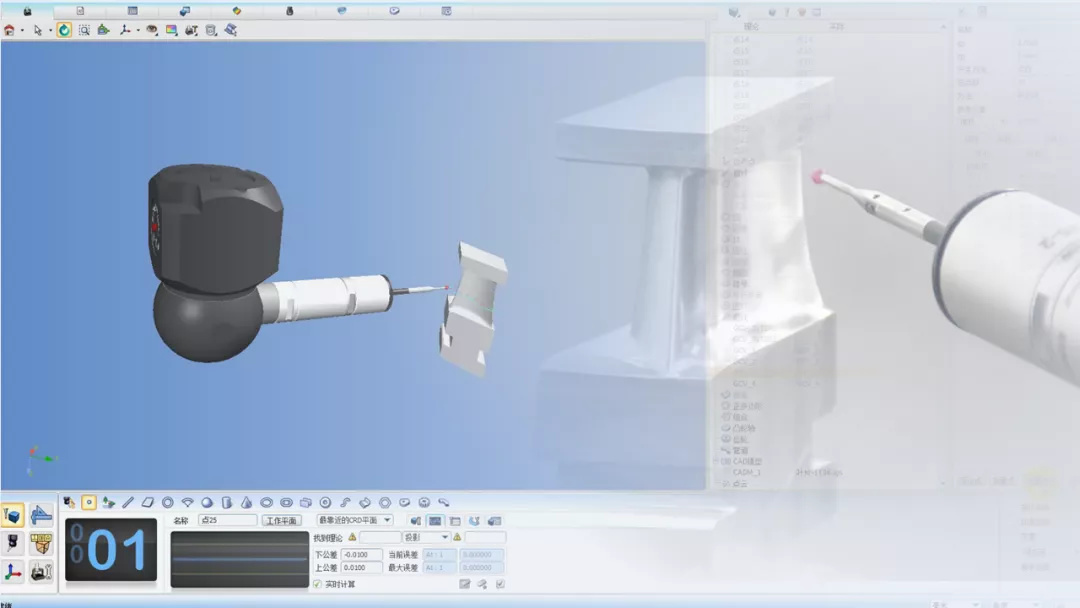

CMM is mainly used in the field of aviation industry to measure the shape,size and other parameters of aircraft components or aviation industrial products such as impellers and blades.In the process of cover measurement,due to the special shape and irregular surfaces or curves of aviation industrial products such as impellers or blades,the generally applicable measurement procedures are no longer applicable,and special measurement procedures need to be designed and developed,Measure and analyze surfaces or curves.Just because of the particularity of aviation products,the demand for CMMs in the aviation industry is also large.

As a very important part of modern precision measurement,CMM provides advanced geometric measurement technology,which provides quality assurance for the entire process of aviation and aerospace manufacturing industry,assists manufacturing enterprises in solving many problems in parts manufacturing technology,and focuses on quality control to improve workpiece quality,reduce scrap rate and shorten product processing cycle.

Key words:

| Related news

13 Jan,2022

13 Jan,2022

13 Jan,2022