Main feature

14

2025

-

08

new cmm instrument

The CMM Instrument stands as a cornerstone of modern metrology, providing unmatched precision for industrial applications. Engineered to measure components with exceptional accuracy, this tool is indispensable for sectors like medical device manufacturing, energy, and electronics. The CMM Instrument ensures that every measurement meets stringent quality benchmarks.

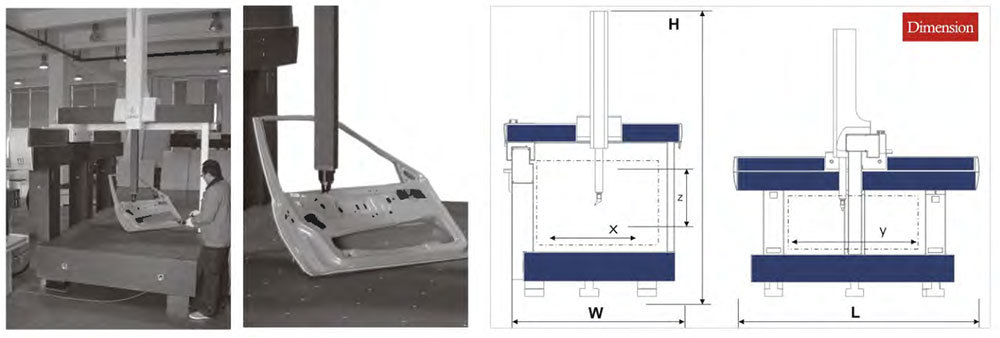

| The integral granite workbench make the machine characterized with the good rigidity,strong bearing capacity,wide workpiece placing space and convenient loading and unloading;The main guide rail is designed to be longer to increase the span of guiding air bearing,and substantially improve the guiding precision of the main guide rail; | The longest axis use high precision tooth-shape driving,which guarantee rather good transmission rigidity;the rest 2 axis adopt high performance synchronous belts,which is not only to get rather fast motion velocity to increase measuring efficiency,but also to reduce transmission inertia to the uttermost to improve the motion acceleration; |

| The elevated structural style is adopted by the Y-direction main guide rail,so that the inertia of the moving parts is reduced,the transmission parts are closer to the center of inertia,and even if the measuring machine with big specification is provided,its good motion characteristics and precision stability can also be guaranteed; | Z-axis adopts the adjustable pneumatic balance device,which can adjust the counterbalance with facility although equipped with different probe systems,so that it can reach the best state. |

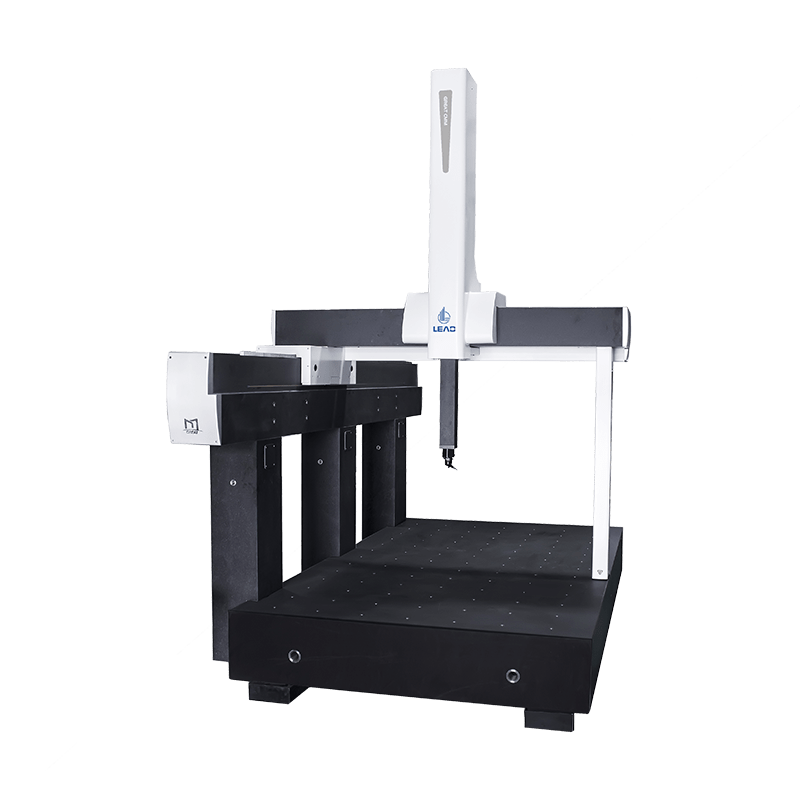

Appearance

The CMM Instrument stands as a cornerstone of modern metrology, providing unmatched precision for industrial applications. Engineered to measure components with exceptional accuracy, this tool is indispensable for sectors like medical device manufacturing, energy, and electronics. The CMM Instrument ensures that every measurement meets stringent quality benchmarks.

Featuring a high-resolution touch probe and advanced optical sensors, the CMM Instrument captures detailed data from even the most challenging surfaces. Its multi-axis mobility allows for comprehensive 360-degree measurements, ensuring no detail is overlooked. The instrument’s intuitive software enables seamless integration into existing production lines, boosting productivity.

With its ability to perform both static and dynamic measurements, the CMM Instrument adapts to a wide range of inspection tasks. Automated reporting functions generate detailed analysis, helping teams make informed decisions swiftly. The instrument’s rugged design ensures stability and repeatability, even in high-volume manufacturing settings.

Choosing the CMM Instrument means opting for reliability, speed, and precision. Its scalable solutions cater to businesses of all sizes, from small workshops to large-scale factories. Elevate your quality assurance processes with this cutting-edge CMM Instrument and stay ahead in competitive markets.

Key words:

| Related news