ABOUT LEAD

02 Oct,2025

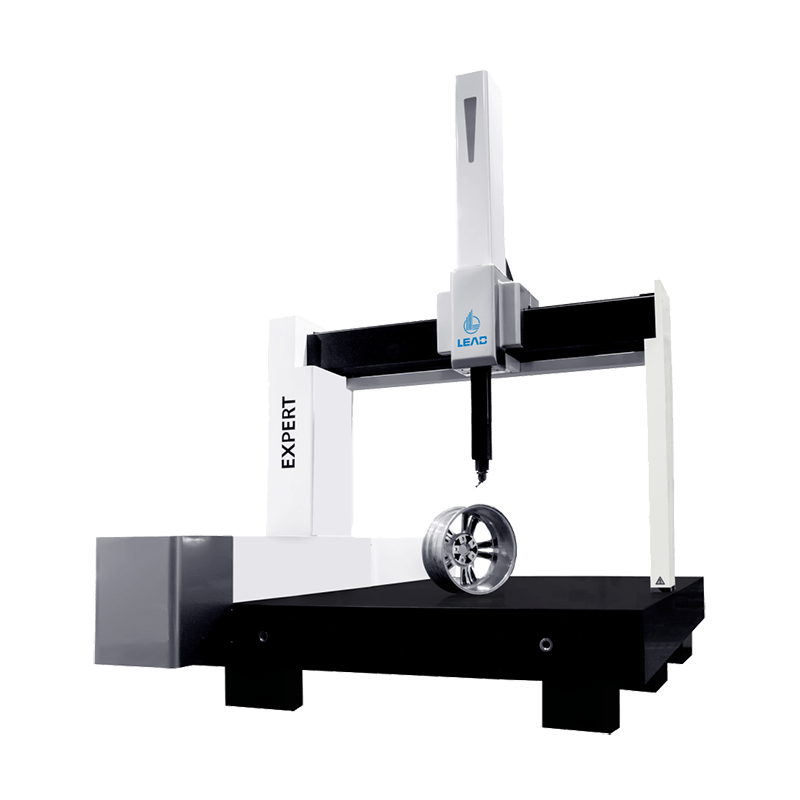

Enhancing Precision: The Role of High-Accuracy Bridge CMMS in Coordinate Measuring Machines

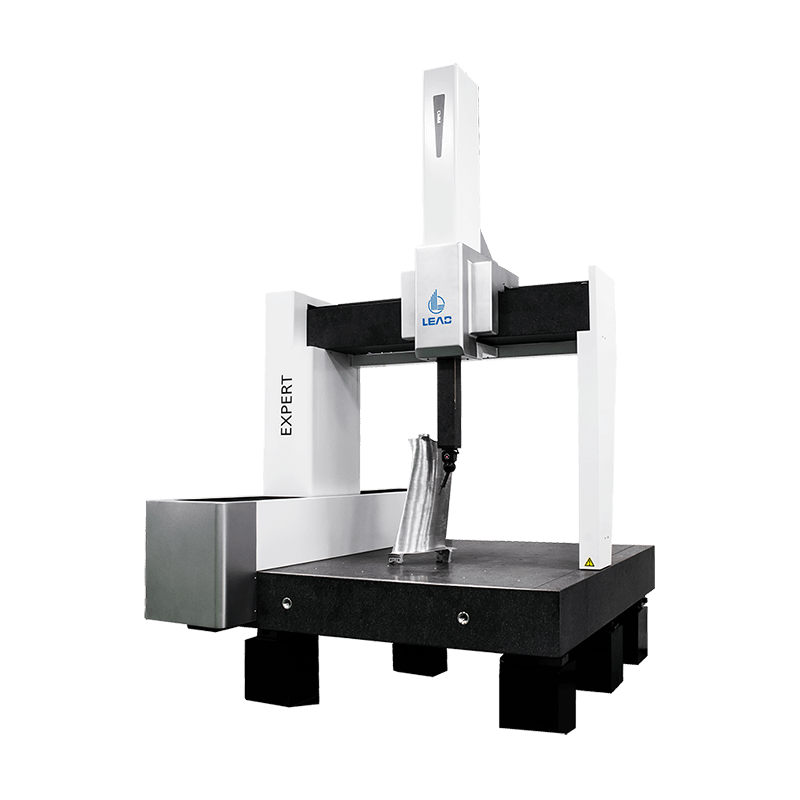

In the competitive landscape of metrology and measurement, the demand for precision is paramount. High-accuracy bridge CMMS play a crucial role in enhancing the performance of coordinate measuring machines (CMMs), which are essential tools for measuring the physical geometrical characteristics of an object. These systems are designed to ensure that measurements are not only accurate but also repea

29 Sep,2025

Happy Mid-Autumn Festival and National Day! LEAD METROLOGY wishes you a happy holiday!

Happy Mid-Autumn Festival and National Day! LEAD METROLOGY wishes you a happy holiday!

25 Sep,2025

Unlocking Precision: How High-Accuracy Bridge CMMS Enhances Measurement Accuracy

Unlocking Precision: How High-Accuracy Bridge CMMS Enhances Measurement Accuracy Table of Contents Introduction to High-Accuracy Bridge CMMS Understanding Coordinate Measuring Machines (CMMS) The Importance of Measurement Accuracy in Manufacturing What Are High-Accuracy Bridge CMMS? Key Features of High-Accuracy Bridge CMMS Applications of High-Accuracy Bridge CMMS Ben

18 Sep,2025

Enhancing Precision with High-Accuracy Bridge CMMS in Coordinate Measuring Machines

In the world of metrology, precision and accuracy are paramount, especially when dealing with intricate parts and assemblies. High-accuracy bridge CMMS (Coordinate Measuring Machines) play a crucial role in achieving these standards. These systems are designed to measure the physical geometrical characteristics of an object with exceptional precision, making them indispensable in various sectors,

11 Sep,2025

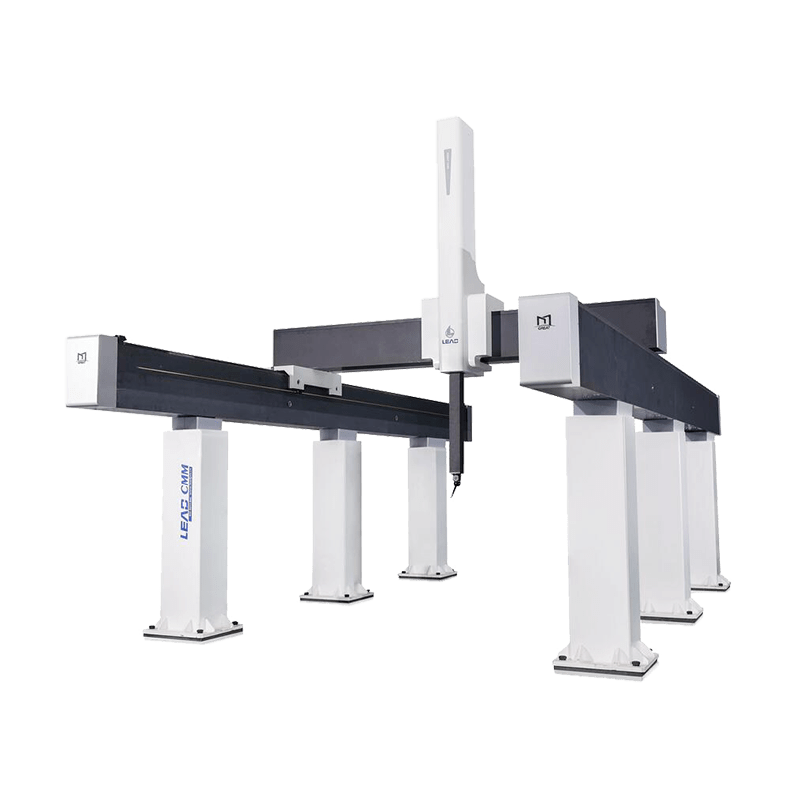

How Single-Side Bridge CMMS Revolutionizes Precision Measurement for the Instrumentation Industry

How Single-Side Bridge CMMS Revolutionizes Precision Measurement Table of Contents 1. Introduction to Single-Side Bridge CMMS 2. The Importance of Precision Measurement in Industry 3. Understanding Coordinate Measuring Machines (CMMS) 4. The Innovation of Single-Side Bridge Technology 5. Benefits of Single-Side Bridge CMMS 5.1 Enhanced Accuracy and Reliabi

04 Sep,2025

Understanding Single-Side Bridge CMMS in Coordinate Measuring Machines

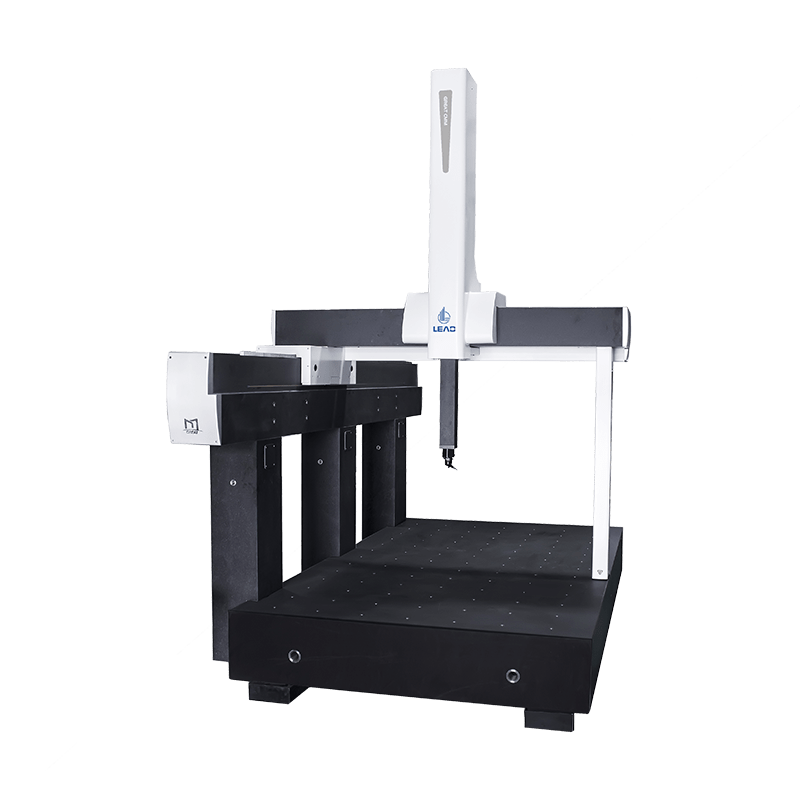

--- In the realm of precision measurement, the single-side bridge configuration in coordinate measuring machines (CMM) has emerged as a noteworthy design choice. This setup typically features a bridge that spans across the measurement area, but is supported solely from one side. Understanding how single-side bridge CMMS operate can greatly enhance the effectiveness of precision measurement tasks.

28 Aug,2025

Maximizing Efficiency with Single-Side Bridge CMMS in Coordinate Measuring Machines Table of Contents Introduction to Coordinate Measuring Machines and CMMS Understanding Single-Side Bridge CMMS Benefits of Using Single-Side Bridge CMMS Effective Implementation Strategies for CMMs Enhancing Accuracy and Precision in Measurements Best Practices for Operational Efficiency

21 Aug,2025

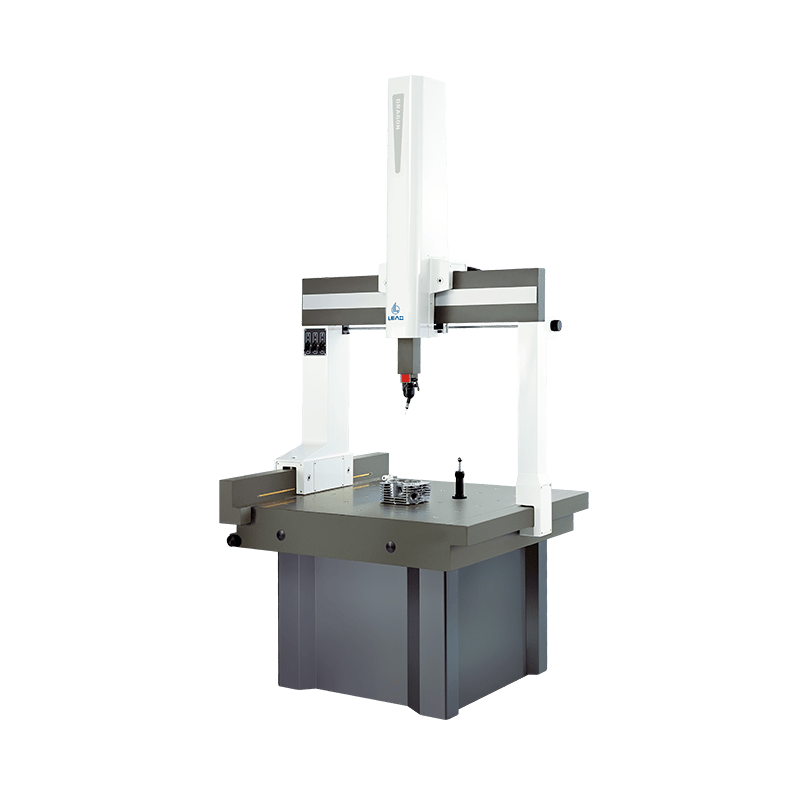

Understanding Three Dimensional Measuring Machines: Precision in Measurement

Three dimensional measuring machines (CMMs) have become an indispensable tool in precision measurement and quality assurance across various industries. These machines play a crucial role in ensuring that manufactured parts meet the exact specifications required for optimal performance. By providing high accuracy and repeatability, CMMs help organizations maintain stringent quality control standard

19 Aug,2025

The three-coordinate measuring machine is the hero behind the scenes in the mold industry #measuring #machine #coordinate #factory #mold #cmm #三坐标 #三次元