Metrology Software Visual DMIS ~Software

TECHNICAL SERVICE &SUPPORT

Visual DMIS is mainly applied to the geometrical dimension measurement of products in the field of aviation,aerospace,automobile,mold and others,as well as the evaluation of form & position tolerance and surface shape of parts,which is very applicable to the software modeling,simulation,verification and other applications in the field of CNC machining equipment.

Many special modules are now available

Simple and intuitive interface

Intuitive and clear measurement interface combined with the measurement process,effective display to customers.There is no tedious confirmation and output process for the interface.

A Easy to lean operation with Drag and Drop

Quick left mouse button drag and drop,Right mouse button for quick function selection Effectively increase the efficiency of the operation Entirely based on MS Windows operation habits.

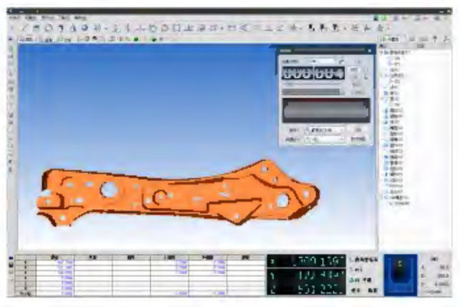

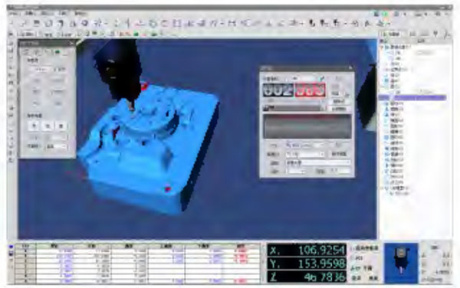

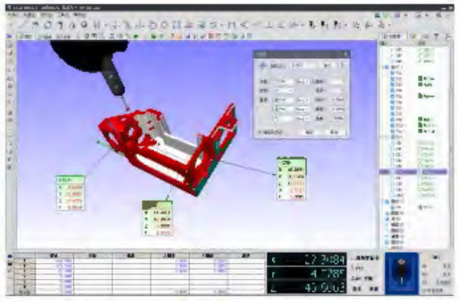

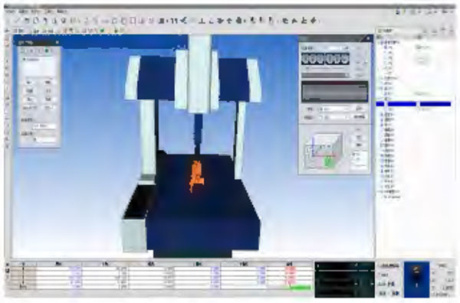

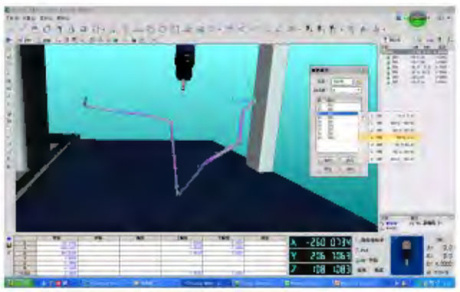

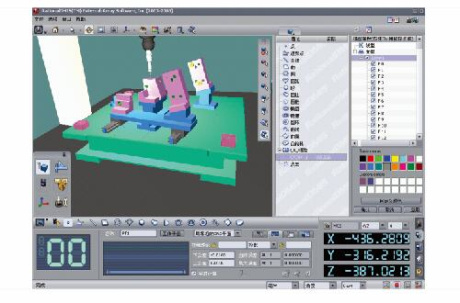

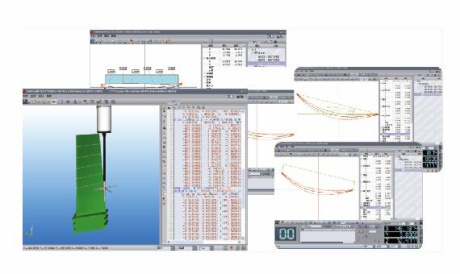

Complete Graphical UI display

In the process of measurement,the morion state of the measuring machine is displayed in real timw,which reflects the actual morion of the probe.The users can esaily rotate the position of the mouse,adjust the proportion of the angle of view,and facilitate the observation of the real time measurement process.

Compatiole with DIMS Standards

Compatible with with DIMS 5.0 standard,support DIMS format bidirectional transmission.

Compatible with various standard DIMS software.No need to use the DMIS conversion tool.

Powerful DMIS self learning program,fast programmmg mode based on CAD graphic object.

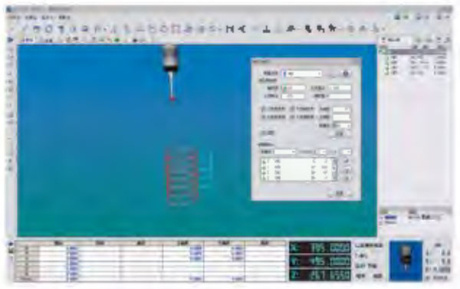

Element measurement

Support Geometric element measurement functions.

Such as:Point,line,plane,circle,ellipse,cylinder,cone,ball,arc,keyway.

Construction function of elements

Construction function support of geometric elements:intersection,middle,projection,

fitting,tangent,parallel.vertical,translation,bias,mirror,extraction,restriction,rotation etc.

Tolerance evaluation

Straightness,flatness,roundness,cylinder,distance,included angle,parallelism,verticality,inclination,coaxiality,symmetry,position degree,round jump,full runout.

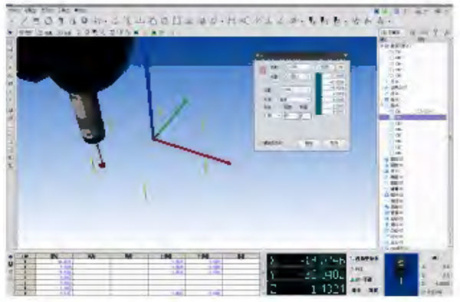

Establishment of coordinate system

Including translation coordinate system,rotation coordinate system,fast 3-2-1 to establish coordinate system,two point offset coordinate system,three point fitting coordinate,reference point system RPS,merged coordinate systems etc.

Programing Functions

The whole measuring functions can automatically prepare by measurement program.

Users can edit the entire program to measure offline analog CAD data.Line offline programming make programming and measurement work separate,improve efficiency and safety.

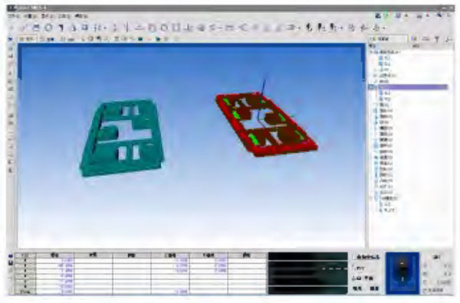

CAD Functions

Supporting various formats of CAD documents,Read the theoretical value and compare it with the actual measurement values.Support Direct off-line analog measurement.

The reverse engmeenng measurement results can be output to CAD system in IGES format.

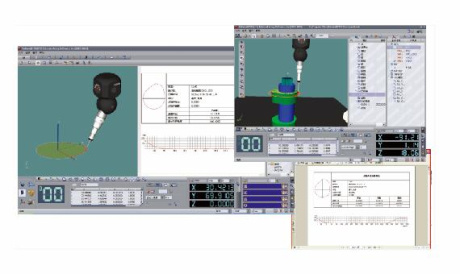

Probes Assembly Module

Real time probe display functions,can define trigger type for all angles of probes.The probe continuous scan ning function provides the possibility of improving measurement efficiency while reducing purchase costs.

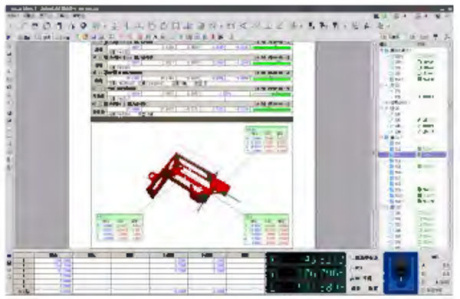

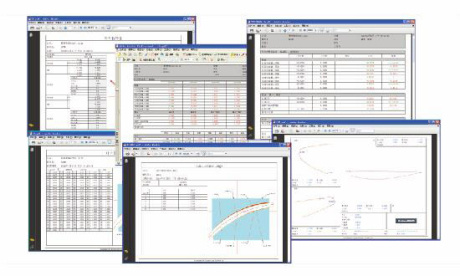

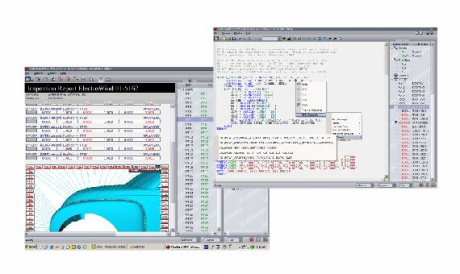

Multipl Reporting Module

Multipl report samples can be easily realized For example,PDF,Word,Excel,TXT,HTML and so on.

Users can also custom the graphic report sedtion and content areas,such as corporate logos,title style and generous personalized reports.

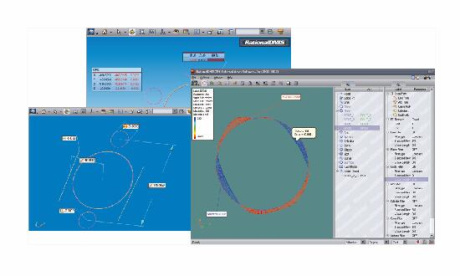

Pipe Module

Pipe module makes optimization to acquisition and output control of pipe data,and the controlled node coordinate is clear at a glance.

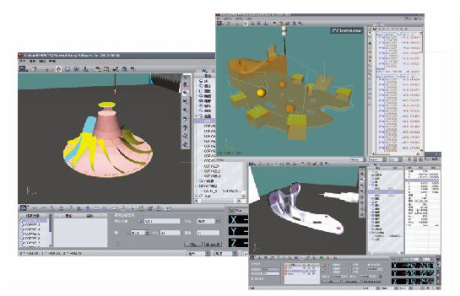

Blade Module

Blade metrology module is mainly applicable for the measuring and analysis of aviation blade and turbine blade.It has the convenient and fast functions of coordi-nate system establishment and mathematic modeling alignment and can complete blade messuring in high efficiency.It can assess blade features,such as the parameters of leading edge profile,rear edge profile,suction surface profile,and pressure surface and assess report graphics.

Worm Module

Two types of worms,i.e.involute cylindrical worm(ZI for short)and Archimedes cylindrical worm(ZA for short),can be evaluated The out put content of the result of the worm is abundant;and the tooth profile error(comprehensive error,tooth profile error and pressure angle error),lead error(comprehensive error,spiral shape error and helical angle error)and t oo th pitch error(adjacent error of tooth pitch and accumulative error of tooth pitch)are provided.

Gear Module

Gear module is mainly used for measuring involute cylindrical gear,including the internal tooth,external tooth,straight tooth,helical tooth and their modified gear,when measuring gear with Visual DMIS software,it is no need to use rotary table.The gear parameter shall be output,so as to carry out the grade judgment on the measunng result according to the different standards(such as ISO,DIN,JIS,AGMA,GB and BS)automatically.

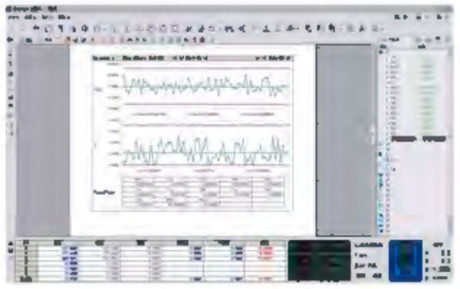

SPC analysis function Module

The mathematical statistics module supports the R chart,histogram,running chart and other charts,carries out the CP and CPK deviation performance analysis,so as to provide the most direct analysis function for the users for quality analysis and control.

Net Report Module

The Network report module allows DMIS programmers to communicate over LAN.DMIS5.0 Core Network report module supporting human-computer interaction,variable declaration,Macro definition,calling external program,Input&Output control,program structure selection,etc.

Metrology Software Rational DMIS ® software

Rational DMIS provide a truly unique User Interface.Dynamic function-sensitive toolbars,action icons,and context-sensitive work areas characterize RationalDMISTM 3D Scanning Software.The graphics window remains visible at all times,maximizing operating efficiency.So intuitive,easy to use,intelligent CMM software in just a few days of training,even if the user did not have much experience,you can easily grasp!

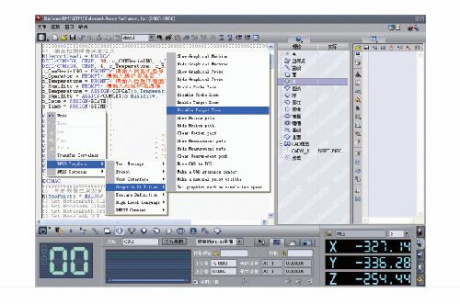

■ Powerful DMIS 5.0 programming.

■ DMIS5.0 core and no need of DMIS converting tool

■ Powerful DMIS self-learning program function

■ DMIS format import/DMO export

■ Rapid programming model based on CAD graphic object

■ DMIS program display in Chinese and English and built-in

■ DMIS Chinese and English script translation tool

■ Intelligent detection Automatically determine the type of smart road test element according to the measuring point and location Route Planning:Automatically create an optimal detection path.Dependency checking:Judge calls the state the current coordinate system and the probe is correct.

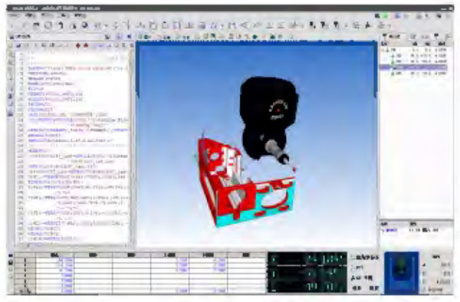

■ Collision resistant detection,detection path preview,real-time simulation Intelligent measuring:automatically assess measured element type according to measure point and location.

■ Intelligent path planning:automatically generate optimum detection path Dependence detection:automatically judge whether used coordinate system and probe head are correct at current situation Quick Panel:unique rapid operation tool to achieve rapid generation of coordinate system/structure/tolerance calculation.

■ Various geometric tolerance evaluation,Graphic Marking element size error.

■ Rich and varied output report Traditional text report output,illustrated output,SPC Statistical analysis reports,various From Fig report errors,

■ HTML Exported in various formats EXCEL,PDF,etc.,user-defined output mode Version to import,edit.

■ Coordinates a variety of powerful elements create a method function Complex workpiece coordinate system is rapidly find a l 3-2 alignment,Fast CAD workpiece alignment,RPS alignment multi-point fit,BestFit proposed Together,iterative alignment(free-form surface workpieces alignment).

■ Complete,fast computing power tolerance Subject to various standard:GB/ISO/ANSI/DIN/AGMA.

Blade module

■ With leaves and aerospace,nuclearpower leave the detection and analysis.

Pipe module

■ Pipeline module can intelligently generate pipeline 3D image accor-ding to theory data,with pipeline coordinate system establishment method built in,conveniently complete the establishment of pipeline coordinate system.There are various pipeline definition methods,from which the user can complete pipeline definition according to personal habits,conveniently completepipeline measuring,and greatly improve measuring efficiency.The complete data and graphic output report make the measured data clear at a glance.

Gear module

■ Gear module is the gear detection software with the best intelligence,usability and integrated imaging in the current market,which can complete the measuring of cylindrical involute gear.

Cam Detection Cam module

■ Cam Detection Cam module can intelligently generate cam profile measuring point,designate parameters of follower,graphically indicate the lift range change in real time,and export standard error evaluation result through graphical contour error comparison.

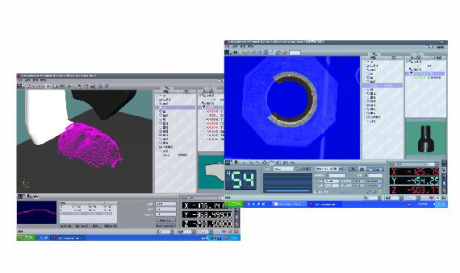

CCD Image Analysis

■ CCD Image Analysis and Laser Scanning CCD image analysis module is mainly applicable for image analysis detection and compound meas-uring.Laser scanning module can carry out high-speed,high-efficiency and high-precision measuring for the workpiece,rapidly gather coordinates and provide data for reverse engineering.

Network Programming

■ Network module can allow the programmer to carry out DMIS offline programming for components and parts on other computers through LAN with no need of addition or installation of new software.It supports human-computer interaction,variable declarations,macro,import in CAD formats of iges,step,dxf for external program invocation,input/output control,and program structure selction,automatic recognition and rapid programming of 2D/3D theory element.Network forms can allow other personnel to check detection data and edit output forms in real time on other computers through LAN.