14

2025

-

05

cheap automated cmm inspection

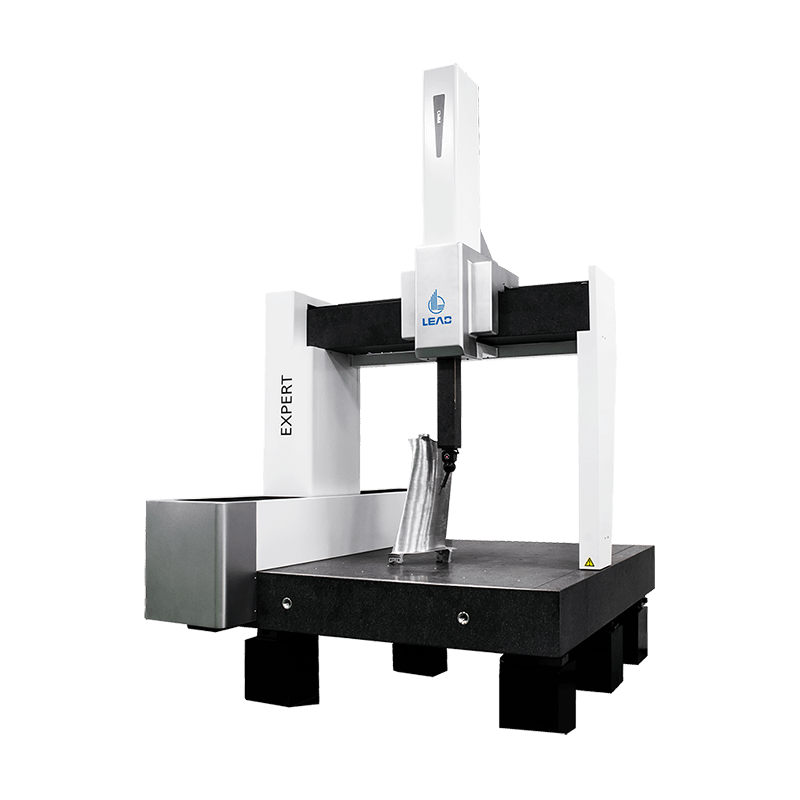

Our Advanced Automated CMM Inspection System offers a cutting-edge solution for high-precision measurement in modern manufacturing environments. Designed to meet the demands of industries such as automotive, aerospace, and precision engineering, this system leverages advanced robotics and AI-powered software to deliver accurate, repeatable inspection results.

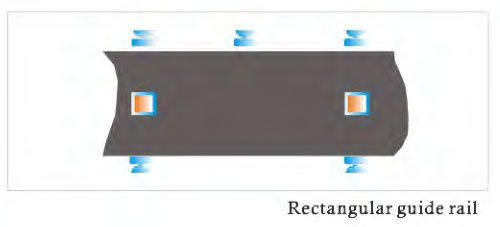

■ The tri-axle is adopted with rectangular guide rail with elaborated design,and the so-called various“Unique“and“Patented”and even strange polygon guide rail structures are abandoned,returning to nature.The correction model upon rectangular guide rail error is simple and practical;the form is most common form in the high-precision measuring machine.

■ The tri-axle is adopted with rectangular guide rail with elaborated design,and the so-called various“Unique“and“Patented”and even strange polygon guide rail structures are abandoned,returning to nature.The correction model upon rectangular guide rail error is simple and practical;the form is most common form in the high-precision measuring machine.

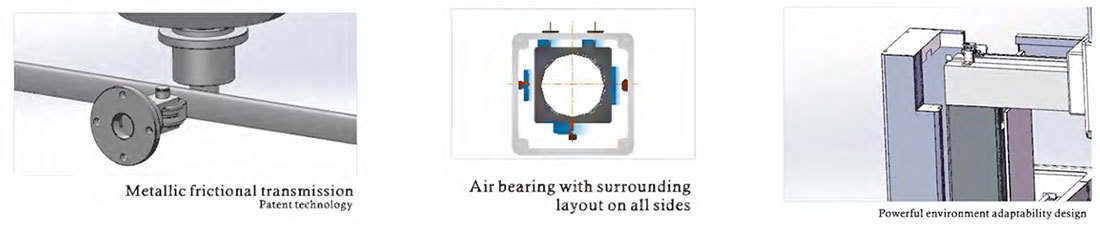

■ Long axis is adopted with the most ideal three-coordinate transmission system recognized by industry currently----metallic frictional transmission.Compared with such gear-shape transmission as common synchronous belt and gear rack,the tooth profile efficiency is eliminated completely to enable that the trans-mission is more steady,effectively eliminate the machine shock brought by the flexible telescoping of synchronous belt and improve the transmission rigidity of measuring machine so as to reach better starting,stopping and positioning capability,which is ideal selection for high-precision scanning measurement.

■ The surrounding-type air bearing layout design is adopted uniformly for tri-axle,and the pre-compression air bearing with high air membrane rigidity is utilized.Through comparison between with other layout and surrounding layout on all sides,the pre-compression force for each air bearing may realize the individual control and non-interference mutually to enable that each air bearing can work under most ideal status.

■ Two columns of measuring machine are adopted with double layer design fully to lower the influence on measuring machine precision by external temperature change and air conditioner’s air supply system to enable that the measuring machine is provided with more powerful environment adaptability.

■ The brand-new pedestal design of measuring machine is completely compatible with high-efficient passive vibration isolation system or positive air vibration isolation system to meet the utilization demand of plant with strong earthquake source and on-line measurement.

Our Advanced Automated CMM Inspection System offers a cutting-edge solution for high-precision measurement in modern manufacturing environments. Designed to meet the demands of industries such as automotive, aerospace, and precision engineering, this system leverages advanced robotics and AI-powered software to deliver accurate, repeatable inspection results.

Equipped with multi-sensor capabilities, the automated cmm inspection can measure complex geometries and features with a level of precision that exceeds traditional manual methods. The system automatically adjusts to varying part sizes and shapes, ensuring consistent measurements across a wide range of components. Whether dealing with simple or highly intricate geometries, this CMM system delivers unmatched accuracy and reliability.

automated cmm inspection Key Benefits:

Superior accuracy with multi-sensor technology

Fully automated, continuous operation for efficiency

AI-driven software for optimized measurement routines

Predictive maintenance for improved system uptime

Data analytics for in-depth performance insights

Flexible integration with existing production lines

By adopting our Advanced Automated CMM Inspection System, manufacturers can enhance their quality control processes, achieve higher levels of precision, and streamline operations for greater productivity and profitability.

Key words:

| Related news