14

2025

-

05

new small cmm machine

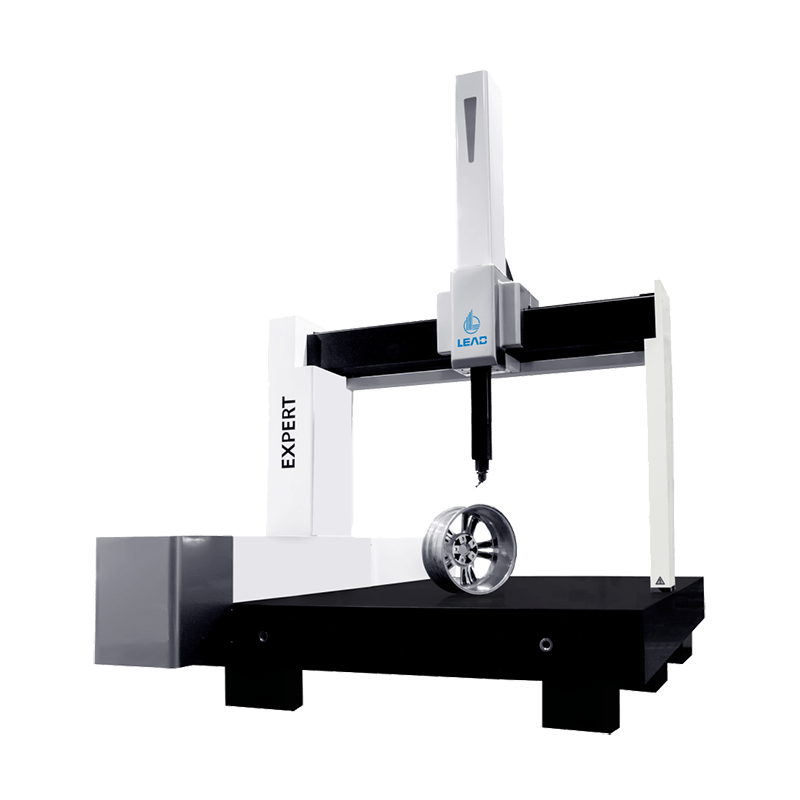

The Small CMM Machine combines cutting-edge technology with a compact design to deliver highly accurate measurements in tight spaces. Its versatility and precision make it an indispensable tool for industries that require detailed inspection and quality control for small parts.

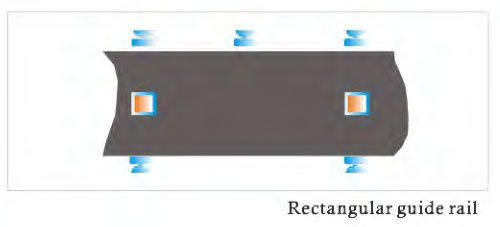

■ The tri-axle is adopted with rectangular guide rail with elaborated design,and the so-called various“Unique“and“Patented”and even strange polygon guide rail structures are abandoned,returning to nature.The correction model upon rectangular guide rail error is simple and practical;the form is most common form in the high-precision measuring machine.

■ The tri-axle is adopted with rectangular guide rail with elaborated design,and the so-called various“Unique“and“Patented”and even strange polygon guide rail structures are abandoned,returning to nature.The correction model upon rectangular guide rail error is simple and practical;the form is most common form in the high-precision measuring machine.

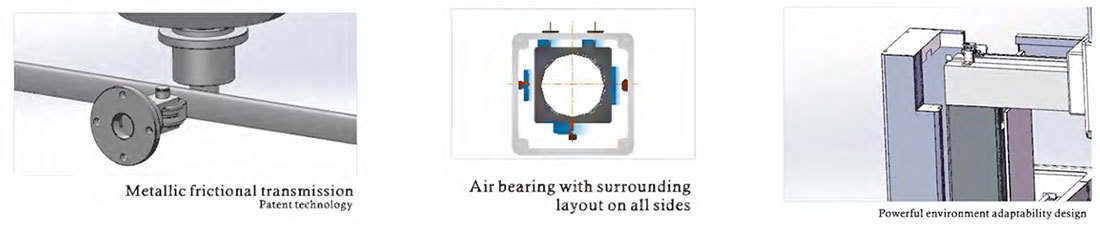

■ Long axis is adopted with the most ideal three-coordinate transmission system recognized by industry currently----metallic frictional transmission.Compared with such gear-shape transmission as common synchronous belt and gear rack,the tooth profile efficiency is eliminated completely to enable that the trans-mission is more steady,effectively eliminate the machine shock brought by the flexible telescoping of synchronous belt and improve the transmission rigidity of measuring machine so as to reach better starting,stopping and positioning capability,which is ideal selection for high-precision scanning measurement.

■ The surrounding-type air bearing layout design is adopted uniformly for tri-axle,and the pre-compression air bearing with high air membrane rigidity is utilized.Through comparison between with other layout and surrounding layout on all sides,the pre-compression force for each air bearing may realize the individual control and non-interference mutually to enable that each air bearing can work under most ideal status.

■ Two columns of measuring machine are adopted with double layer design fully to lower the influence on measuring machine precision by external temperature change and air conditioner’s air supply system to enable that the measuring machine is provided with more powerful environment adaptability.

■ The brand-new pedestal design of measuring machine is completely compatible with high-efficient passive vibration isolation system or positive air vibration isolation system to meet the utilization demand of plant with strong earthquake source and on-line measurement.

The Small CMM Machine combines cutting-edge technology with a compact design to deliver highly accurate measurements in tight spaces. Its versatility and precision make it an indispensable tool for industries that require detailed inspection and quality control for small parts. With its easy-to-use interface and highly adaptable features, the Small CMM Machine is perfect for small-scale manufacturing environments where space and efficiency are of utmost importance.

One of the key benefits of the Small CMM Machine is its ability to measure components with micron-level precision. It is equipped with high-resolution probes that ensure consistent accuracy across a wide range of materials, such as metals, plastics, ceramics, and composites. This makes it ideal for industries such as electronics, automotive, and medical device production, where part quality is critical for functionality and safety.

From improving production efficiency to enhancing the overall quality of your products, the Small CMM Machine is a must-have for any company focused on delivering high-quality components with exceptional accuracy.

Key words:

| Related news